A 10 MW (Megawatt) solar farm is not just a large-scale project; it is a full-fledged infrastructure investment. For investors, Independent Power Producers (IPPs), and large C&I (Commercial & Industrial) enterprises looking at captive power, this scale represents a significant commitment to sustainable, long-term energy generation.Naturally, the first and most critical question on every stakeholder’s mind is the bottom line: What is the real, all-inclusive cost of setting up a 10 MW solar farm?While it’s tempting to look for a simple “per-megawatt” number, the truth is far more nuanced. As of 2025-2026 in the Indian market, a benchmark estimate for a 10 MW solar farm cost typically falls within a broad range of ₹35 crores to ₹50 crores.

Why such a significant ₹15 crore gap?

A utility-scale solar project is a complex puzzle of engineering, real estate, technology, and finance. The final price tag is not a single item but the sum of many variable parts. To build a bankable project, you must understand exactly where your capital is going.

Let’s move beyond the estimates and break down the 5 key factors that will ultimately determine your final project cost.

Factor 1: Land — The Biggest Variable in 10 MW Solar Farm Cost

In solar power, “location, location, location” isn’t just a real estate mantra—it’s a primary cost driver. A solar farm is, at its core, a land-intensive project.

- Land Area & Cost: The industry rule of thumb for a 10 MW ground-mounted project is 40 to 50 acres of shadow-free, usable land. This can change based on panel efficiency and mounting technology (trackers need more space), but it’s a solid starting point. The price of this land is the biggest variable—a parcel in a remote, arid region of Rajasthan will be vastly cheaper than land near an industrial hub in Maharashtra.

- Land Type & Conversion: Is the land agricultural or barren? Acquiring and converting fertile agricultural land (NA – Non-Agricultural) is both more expensive and riddled with regulatory hurdles. Barren, non-arable land is ideal.

- Civil & Site Preparation Work: The land’s cost doesn’t end at its purchase. You must budget for significant civil works:

- Topography: Is the land flat? Undulating or rocky terrain requires extensive leveling, grading, and foundation work, adding cost.

- Soil Testing: Geotechnical reports are essential to design the correct foundations.

Infrastructure: This includes building internal access roads, perimeter fencing, CCTV security, and a control room.

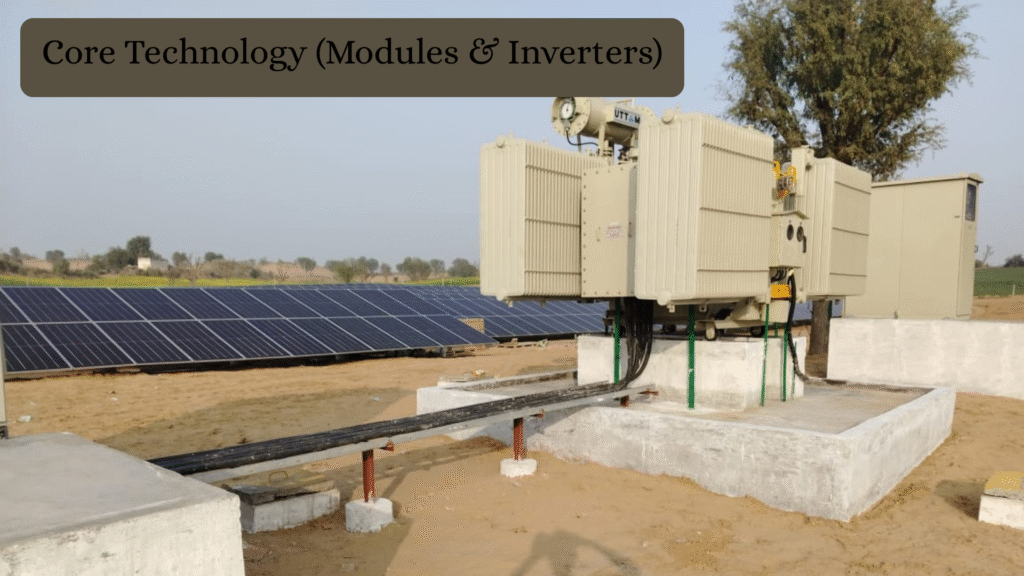

Factor 2: Core Technology (Modules & Inverters)

This is the “engine” of your power plant and typically accounts for 40-50% of the total project cost. The technology choices you make here will define your plant’s performance for the next 25 years.

A. Solar Modules (The Panels)

- Technology: High-efficiency Monocrystalline PERC (Mono-PERC) panels are the dominant market standard.

- New Generation: Many new projects are opting for TOPCon or Bifacial modules. Bifacial panels generate power from both sides, increasing generation (kWh) by 5-15%. They cost more upfront, but the long-term ROI is often compelling.

- Bankability: You must use panels from a Tier-1 manufacturer (e.g., Jinko, LONGi, Adani Solar, Waaree) and ensure they are on the ALMM (Approved List of Models and Manufacturers) to secure financing.

B. Inverters (The Brains)

Inverters convert the DC power into grid-usable AC power. For a 10 MW plant, you have two main choices:

- Central Inverters: One or two massive, high-capacity inverters.

- Pros: Generally lower cost per watt, simpler architecture.

- Cons: A single point of failure. If the inverter goes down, your entire 10 MW plant is offline.

- String Inverters: Hundreds of smaller, distributed inverters.

- Pros: Better redundancy (if one fails, you only lose a small string), easier maintenance, and better performance.

- Cons: Slightly higher upfront cost.

Investor’s Tip: Your choice of technology (Bifacial vs. Mono, String vs. Central) will define your plant’s generation and maintenance costs for 25 years. This is not the place to cut corners.

Factor 3: Balance of System (BoS)

This is the industry term for everything else required to make the plant function.

A. Mounting Structures

- Fixed-Tilt: Structures are “fixed” at an optimal angle. This is the simpler, cheaper, and most common option.

- Single-Axis Trackers: These structures “track” the sun from east to west, boosting generation by 15-25%. However, they add significant capital and maintenance costs.

B. Cables & Switchgear

The “nervous system” of the plant. This includes thousands of meters of specialized DC/AC cables, combiner boxes, and high-voltage switchgear. Using high-quality, properly-sized cables is non-negotiable for safety and minimizing energy losses.

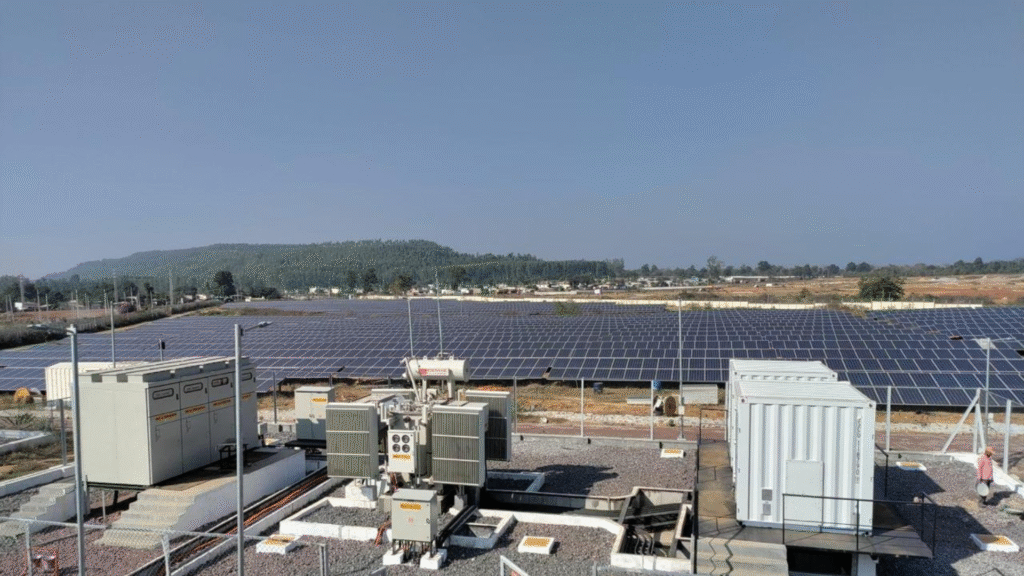

Factor 4: Grid Evacuation & Connectivity

You’ve generated 10 MW of power. Now you have to get it to the grid. This is a highly technical and expensive part of the project.

- Distance to Substation: This is the key. Is the nearest DISCOM (Distribution Company) substation 1 km away or 20 km away?

- Transmission Line: You are typically responsible for building (and paying for) the transmission line from your farm to the substation. A 20 km, 33kV line is a massive project in itself, costing crores.

- Substation Bay & Transformers: You’ll need a large power transformer at your site and may need to pay for a new “bay” (a connection point) at the DISCOM’s substation.

Approvals: The regulatory and technical approvals from the grid operator are complex and time-consuming.

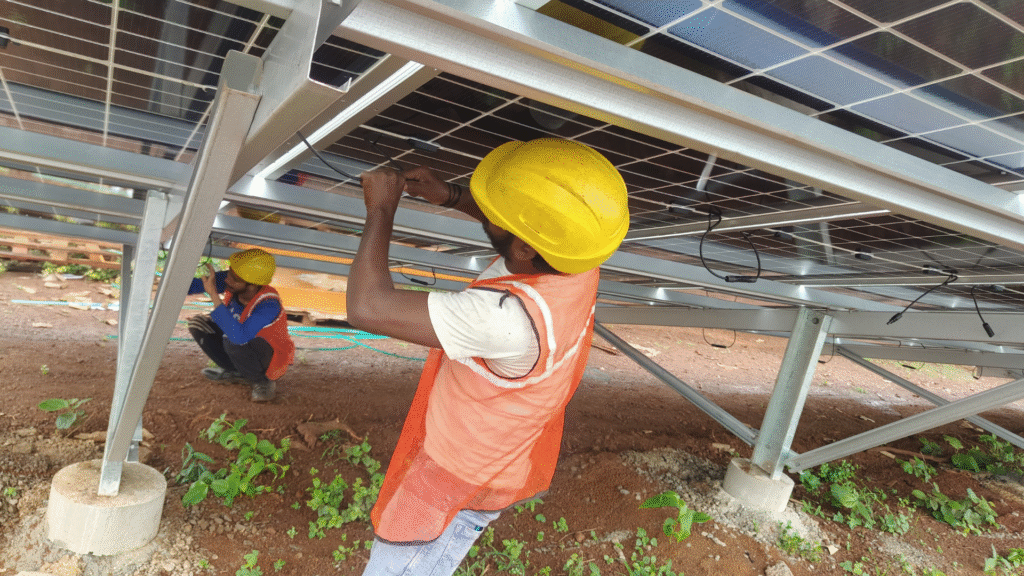

Factor 5: The “Human” Costs (EPC, O&M, & Approvals)

This final category covers the expert services required to bring the plant to life and keep it running.

- EPC Partner (Engineering, Procurement, and Construction): This is the single most important partner you will select. A high-quality EPC partner does not just install panels. They:

- Perform detailed engineering and design to maximize generation.

- Procure high-quality, bankable components.

- Manage the entire construction, logistics, and labor.

- Commission the plant and guarantee its performance.

Investor’s Warning: Choosing the cheapest EPC is the most expensive mistake you can make. A 1% drop in your plant’s annual generation due to poor design or installation will cost you far more over 25 years than any upfront savings.

- Approvals & Liaising: The “soft costs” of paperwork, including fees for state nodal agencies, DISCOM approvals, and CEIG (Chief Electrical Inspector) clearance.

- O&M (Operations & Maintenance): This is an ongoing cost, typically ₹50 lakh to ₹80 lakh per year. This includes 24/7 monitoring, security, and regular (often robotic) cleaning of the panels.

At a Glance: 10 MW Solar Farm Cost Component Breakdown

To simplify, here is a typical breakdown of where your money goes. (Note: The percentages are estimates and will vary greatly based on land and grid connectivity costs).

| Component | Estimated % of Total Cost | Key Considerations |

| Solar Modules (Panels) | 40% – 50% | Tier-1, ALMM, Mono-PERC vs. TOPCon/Bifacial |

| Land & Site Prep | 10% – 20% (Highly Variable) | Location, topography, acquisition vs. lease cost |

| Inverters | 5% – 8% | Central vs. String, warranty, efficiency (MPPTs) |

| Balance of System (BoS) | 12% – 18% | Mounting structures (fixed vs. tracker), cables, civil work |

| Grid Evacuation | 8% – 15% (Highly Variable) | Distance to substation, transformer, transmission lines |

| EPC & Soft Costs | 5% – 10% | EPC partner quality, permits, O&M, financing costs |

Beyond Cost: The Real Question is ROI

While the 10 MW solar farm cost of ₹35-50 crore is the headline number, no serious investor spends that kind of money without a clear path to returns.

A well-designed 10 MW solar farm in a high-sunshine state like Rajasthan or Gujarat will generate approximately 1.4 to 1.6 crore units (kWh) of electricity in its first year.

Your ROI depends on how you use that power:

- Captive Consumption: If you are a large factory paying a commercial tariff of ₹8/unit, this plant saves you ₹11.2 to ₹12.8 crores per year. The payback period is incredibly fast, often just 4-6 years.

- Selling to the Grid (PPA): If you are an IPP with a 25-year Power Purchase Agreement (PPA) at, for example, ₹3.00/unit, you have a stable, predictable revenue stream of ₹4.2 to ₹4.8 crores per year for 25 years, offering a solid, infrastructure-like return.

Conclusion: Your Next Step

As we’ve seen, the final 10 MW solar farm cost is not a fixed number. It is a dynamic figure based on your choices in land, technology, engineering, and partners.

This is not an “add to cart” purchase; it is a bespoke infrastructure project. The only way to get a truly accurate number for your project is to move to the next step.

Ready to build your 10 MW asset? The journey begins with a detailed, site-specific analysis. Contact our utility-scale solar team today for a consultation. We can help you develop a Detailed Project Report (DPR) that outlines precise costs, timelines, and generation forecasts for your specific location.

Frequently Asked Questions (FAQ) about 10 MW Solar Farm Costs

Q1: What is the cost per MW for a 10 MW solar farm in India?

A: The benchmark cost per megawatt (MW) typically ranges from ₹3.5 crore to ₹5.0 crore. The final cost depends heavily on land, grid connection distance, and the quality of components (like trackers or bifacial panels) used.

Q2: How much land is required for a 10 MW solar farm?

A: As a general rule, you will need approximately 40 to 50 acres of land for a 10 MW ground-mounted solar farm. This area can be slightly less with high-efficiency panels or more if you use single-axis trackers.

Q3: How much money can a 10 MW solar farm make per year?

A: This depends on the model. For captive use (in a factory), it can save ₹11-13 crores annually on electricity bills. If selling to the grid under a PPA (e.g., at ₹3/unit), it can generate ₹4.2 to ₹4.8 crores in yearly revenue.

Q4: What is the typical payback period for a 10 MW solar investment?

A: The payback period varies. For a C&I (Commercial & Industrial) captive project with high electricity tariffs, the payback can be as fast as 4-6 years. For an IPP (Independent Power Producer) selling to the grid, the payback is longer, typically 7-9 years, but provides stable returns for 25 years.

Q5: What are the main approvals needed for a 10 MW solar project?

A: The process is complex, but key approvals include: Land (NA conversion), Grid Connectivity (from the state DISCOM), Technical Feasibility Report (TFR), PPA execution (if applicable), and final safety clearance from the CEIG (Chief Electrical Inspector).